Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

Leaderboard

Popular Content

Showing content with the highest reputation since 03/29/2024 in all areas

-

It's is used at the assembly line/factory, not used by PIWIS or anything, has a data line from the DME only though that can carry the same info from DME, but no other data lines included in it like the PIWIS/OBDII connector.3 points

-

Most factory installed Zenon headlights require a separate controller for the HID system.2 points

-

Very easy task. You first have to jack the car and have it level properly. Tool needed: 10 mm allen wrench for the transmission ports. I got one mount on a socket. 17 mm socket for the front wheel drive transmission. 10mm sockets for the cover plastic nuts Very small and thin common screwdriver for the panel clips. Torque wrench. A pump for the fluid. I use a Motive Power Fill (about $85.00 with a shut-off valve) Parts needed: About 5 (1/4) liters of Mobilube PTX 75W90. I did not choose any alternate oil. I prefer to stay with Porsche and Loren recommendation! Be ready for a chock, this oil is expensive!!! Here in Montreal I could only found 20 liters container and I finally went to the dealer and he charge me $261.00 for 5 liters!!!!! And a crush washer for the transmission drain part # 900 123 118 30 ($0.52) Note : It is the only port with a sealing ring. Lets start with the front wheel drive transmission. First you have to remove the plastic cover. It is held with 6 clips and 4 plastic nuts. The best way I've found to remove those clips without damaging them is to use a small thin screwdriver and release the small clip through the opening on one side. Panel removed: Now you can see the drain port: And the fill port: Drain the fluid by opening both ports: Note: My drain port had a magnet to pickup metal chips. (There was sludge and little bit of metal shaving, normal wear to me) And reinstall the drain plug when no oil is coming out anymore: Torque is 21 ftlb for both ports. And fill through the fill port until fluid is coming out. Let it drain and when it stop you can look at the level with a mirror. It should be equal with the bottom edge of the port. About 1.5 liters is needed. Having a shut-off valve and a level indicator on the fill bottle was really useful. Reinstall the fill port and torque to 21 ftlb. And reinstall the plastic cover....Thats it for the front wheel drive transmission. The transmission is easy to reach. No panel to remove. An 10mm allen wrench is needed to remove the ports. Remove the fill and drain ports. Drain the fluid. Note: A magnet is install on the drain port and had metal but was the first oil change and suppose to be normal.... Reinstall the drain plug with a new seal part# 900 123 118 30 and torque the plug to 22 ftlb. Fill the transmission through the fill port until level comes to the bottom edge of the port. About 3 liters needed. Reinstall the fill plug (no seal needed) and torque to 22 ftlb. Hope this will help any TT owners out there! Do not hesitate to ask questions or add comments. Thanks, J.P.2 points

-

Attended an introductory high performance driving school at the National Corvette Museum Motorsports Park in my new to me 2002 996.2 C2! It was awesome! Learned a lot and had a great time. We had classes, autocross, & track time all day long. There were only 10 of us so we pretty much had an instructor to each pair all day. I learned that I am slow & can’t rev match downshift very good at all. Also learned that my stock suspension car has some body roll, understeer, & some brake feel issues. I’m thinking about some braided brake lines, good fluid, new tires, & some Ohlins suspension to start with. I have read a lot of threads about suspension, sway bars, tops, and linkages. Is there a definite go to for top mounts? I’ve been looking at the Ohlins or Tarett mounts. I want to do the coil overs first & then the sway bars. Any comments or recommendations are appreciated. The car will be used as my sunny day driver & once a month track day experience.1 point

-

1 point

-

1 point

-

1 point

-

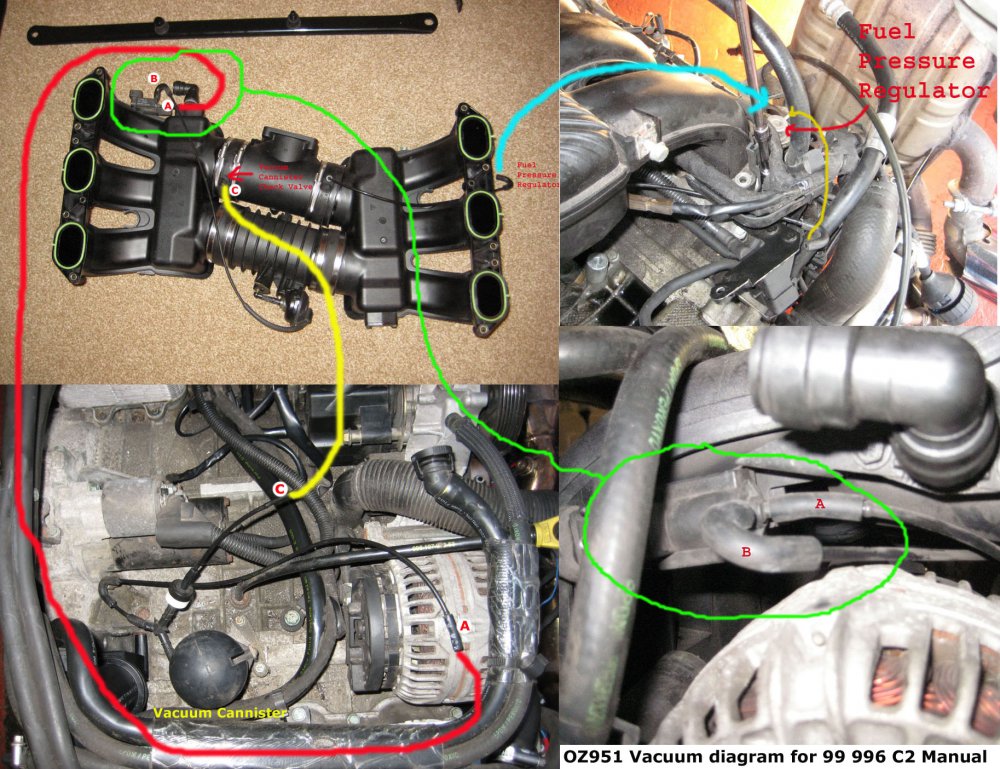

Welcome to RennTech The beauty of the Porsche sports exhaust system is that if you leave the vacuum connections disconnected, it is in the loud position at all times, giving you max flow. I would simply remove the wire the previous owner installed which decreases both sound and performance and enjoy the ride.............and the sound.1 point

-

Jake has probably forgotten more than most of the rest of us combined know about these engines, so he is a trusted source. You would be wise doing both sides, the IMS, the RMS, new plug tubes, etc. all at the same time; you really don't want to go back in there six months down the road.............😉1 point

-

1 point

-

Had to give it another go today. Window was working fine since my last post but suddenly two days ago it started jumping up and down again, which is a pain because I just replaced the door courtesy lights. Now I have a light show in addition to the jumping window. So I replaced the interior door handle microswitch and sprayed every electrical connection except the big door latch with electrical cleaner. I then put dielectric grease in each socket and put it all back together and...still have the jumpy window and the light show. It seems like the trigger for this activity is driving over bumps and when I push on the door handle near the storage cubby. Am I right in thinking that there is a problem with the wires connecting to the back of the interior door handle?1 point

-

From the Lost Radio Code FAQ... "Can you give me a code for my PCM? These units are manufactured jointly by Siemens and Becker, and the only place where you can get the codes required is from the dealer/OPC. The PCM’s require two codes, the ICS/Siemens code, and a Becker code. The ICS is the first code requested. Sorry, the only place you can get a PCM code is from a dealer/OPC."1 point

-

1 point

-

Looks like mine when I got it from auction. Two airbags were bad, the rear hydraulic antiroll bar line was blown and the pump was trashed and I had a list like this. Keep plugging, you'll get it done!1 point

-

Managed to get all 12 (I was mistaken on the number earlier). A few important notes for anybody attempting to tackle this. 1) USE REALLY HIGH QUALITY DRILL BITS! If a bit breaks in the head, you’re far f***ed 2) Use tons of cutting grease/fluid after every 10 seconds or so of drilling to keep bit tip cool and lubed. Make sure not to strain harden bolt going as fast as you can. Take your time and clear chips out of flutes often. 3) DRILL AS PERFECTLY STRAIGHT AS HUMANLY POSSIBLE. Can’t stress this enough. If it’s not straight you will drill the bolt and the head out. When you go to tap, you may dislodge the remaining broken bolt piece. This will cause tap to seize up and hole to be ruined. Then you’ll have to go over size with helicoil 4) You will need extended (6” long) drill bits in sizes 3/16, 1/8, 1/4 and 17/64 (or letter J 7mm). Drill but stops help too. DONT DRILL PAST THE BOLT OR YOU ARE IN THE WATER JACKET! I drilled in steps. Smallest to largest. Smallest pilot hole through center. About 20mm of thread engagement to drill through and a 3mm air gap in between end of bolt and head so when you get through you’ll feel it. Don’t keep going! 5) You will have to remove the thermostat and drain the coolant in order to be able to drill that last one on drivers side straight on. The thermostat housing eclipses the bolt by like 1/4”. Also, undoing the mounting for the coolant tube helped make room for drill head. 6) Stainless hardware or very high grade hardware and nickel anti-seize will last forever. I also used a torch and an air hammer to heat up and remove all 6 manifold collector studs and replaced with grade 10.9 bolts and nuts. 7) Have a face shield and long sleeves because it will be raining hot molten metal chips down in your face for 3 days straight 8 If you have the funds I highly suggest stromski racings drill guide kit but it is pricey for a one time use item 9) when tapping use grease, check x and y to make sure you’re staying straight, remove and clear chips out of flutes often and use the 3 turns forward 1/2 turn back method 10) vacuum fill the cooling system or fight bleeding1 point

-

1 point

-

Follow the wires from the light and fan down the deck lid to the right side of the engine compartment. You will find a connector there (X23) - disconnect it and make sure the pins are good and clean.1 point

-

1 point

-

1 point

-

Have checked your clutch pedal and boost spring to see that it is working correctly? Are you using a pressure bleeder (under 20 PSI)?1 point

-

1 point

-

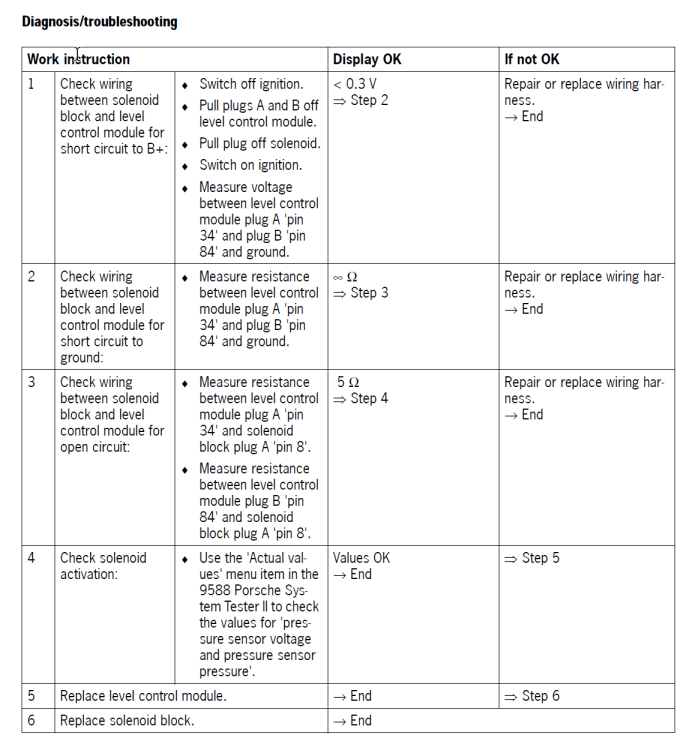

Fault code 1772 Pressure sensor signal wire Possible cause of fault - Short circuit to B+ in the wiring of pin 84 of the level control module - Short circuit to ground in the wiring of pin 84 of the level control module - Open circuit in the wiring of pin 84 of the level control module - Level control module receives implausible signal from pressure sensor - Pressure sensor faulty - Level control module faulty1 point

-

1 point

-

1 point

-

If your car is MY2003 and later then it is a MOST bus car, i.e., the audio units, radio, CD, amps, communicate with each other using fiber optics. That box is a MOST bus interface for the PCCM+ to be able to communicate with the amps. All MY2003+ cars need that box.1 point

-

We have installed many B&M shifters over the years, and they have proven to be one of the best when it comes to durability, and in fact we have never had to replace one. More likely, you have a cable or cable end issue.1 point

-

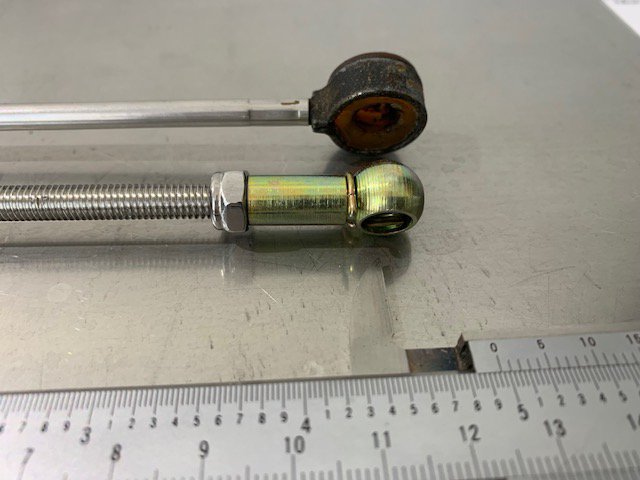

Reviving an 18 year old thread for a reason. Old Porsches often times end up in the hands of enthusiastic folks that are on a budget. Such is the case of my 26 year old '97 986, with 57K. When things happen, old Porsches need a less expensive and better solution than factory parts. So to cut to the chase: couple of weekends ago, the Boxster comes out of hibernation in the garage, fixed the windshield washer, the oversensitive horn (teflon washers under the air bag), and replaced the ignition switch (Audi part), all for under $20, couple of hours in the sun. Took it for a spin and 8 miles from the house left me with just 3rd and 4th gears (good thing I did not need reverse). Got it home, though starting in 3rd was not fun. Sure enough, the side-to-side portion of the shift linkage fell off at the bottom 8mm ball of the transmission ('97, '98+ have 10mm). So, options were a new Porsche linkage with the same plastic/rubber ball sockets ($200+), or a metal replacement for $125. And NEITHER comes with the 8mm ball socket needed for a '97. Solution, as someone posted somewhere (can't find it again), was two metal ball sockets, an 8mm for the bottom and 10mm for the top, a 304 stainless M6x1.0 threaded rod, 304 stainless locking nuts. See pix if I can upload. Had a heck of a time finding 8mm metal ball socket. Altogether $20 and an hour of work duplicating the factory linkage. Exactly 126mm center-to-center of the ball sockets. A good glob of bearing lube in each ball socket and the linkage was installed in minutes, without taking off the triangular aluminum underbelly. The side-to-side motion is more precise with the metal ball sockets, with plenty of freedom for the linkage to move. Thus begins the endurance test. The factory linkage WILL leave you stranded sooner or later. Mine had a retainer clip on top but nor on the bottom 8mm ball. Anyway, if anyone is interested in a linkage for a '97 (8mm and 10mm balls) or a later model (10mmx2), I can precision make them for about $60, including the above materials and an hour or so of my time. If you are not driving like a grandma (that's how I drive) or are racing your Boxter, you got to have a metal linkage. I may eventually post a dozen of my frugal fixes that have stood the test of time, have this Boxster going on 10 years. BTW the top 10mm side of the old factory socket is also toast.1 point

-

I think it is more the other way around; K40 are well known for their "hidden" systems that range from radar and/or laser detection systems, as well as highly illegal jammers to block both radar and laser signals. Even their very basic systems start at around $700 for their portable units, so they are rather expensive to say the least. I have never been a fan of their hidden systems as they tend to mount the signal receivers low to the ground (in the front grill or near the rear license plate for example) which dramatically reduces their effective range. To offset this limitation, K40 turned up the wick on signal sensitivity, which tends to lead to constant false signals, as you just found out 😉1 point

-

it's 1 of 2 coolant temperature sensors and the auxiliary coolant pump replace all 3 and the problem will go away -- had this issue for a short time on my S Hybrid, replaced the 2 sensors (one is on the back of the engine ) and the auxiliary water pump ( which can be had on ebay for 1/5 of the Porsche price, from the OE manufacturer ... Pierburg ).... coolant sensors are cheap all over the net1 point

-

In case it helps someone else in this situation, I discovered removing the fan and shroud allows sufficient access to remove the pump. This means no radiator work is needed besides the shroud removal. Should I need to drain or remove the rad in the future, I'll just take off the fan housing (and trust me, that's not a fun job, either!) You then then have access to the lower radiator hose to release the clip.1 point

-

I have the pleasure of dealing with suspension problems on my 2011 Cayenne turbo. I learned a lot about this system through trial and error. I will give you the highlights of what I know.... When it will not inflate it is obviously due to lack of pressure. This system uses nitrogen. If you fill with nitrogen it will fix your problem at least for a little while. You probably have a leak somewhere and it has caused the compressor to go bad. I borrowed a friends nitrogen bottle and purchased some parts from Porsche and snap on and bought an adaptor from a hydraulic shop and used an AUTEL scanner (pro grade that will calibrate suspension) to do a fill. After filling I sprayed the struts one at a time to figure out where my leak was. I had a leaky left front strut. I replaced both front struts and the compressor and filled with nitrogen and the car has been good for about 2 years. A Porsche expert diagnosed the car for me as just needing the compressor and he was happy to replace for about $4000. I said no thank you and fixed myself after paying for his diagnosis which was only partially correct. I hope this helps.1 point

-

From the Lost Radio Code FAQ... "CDR-23 (or later): These radios do not have a security code - that is, not that the user enters. These radios are security tested on the MOST (fiber optic bus) system to see if they are the "programmed" radio. The radios are programmed and recognized by the car’s DME and can only be replaced by a shop with a PST2 or PIWIS. These radios will not request a code when battery power is disconnected."1 point

-

1 point

-

Thanks for the help. Well, my mechanic downloaded a set of "european cars drivers" for his scanner, deleted the fault and everything went good, so now the tiptronic works flawlessly. Thanks.1 point

-

The above post was very helpful, and it was just about the only resource I could find on line. By way of thanks, I offer the following additional details, in hopes of helping the next guy in my former predicament: Attached is a photo showing my old (bottom) and new (top) striker plate assemblies. The old one is rusted around the base of the hook, and frozen in the open (out) position. Operating the latch on the (open) hatch, as advised by Bigbuzuki above, had no effect at all. Before I found B's posting, nothing else I saw on line even suggested that the hook should move; but it becomes obvious on inspection of the striker plate assembly, with its electrical connections and housing, that it has a motor (and perhaps a sensor). I replaced the assembly with the "new" part shown in the photo ($35 on ebaY) and it is operational again! When the hatch is opened, the hook moves to the open (out) position; the motor runs audibly, but the operation of the hook is not visible. Operating the latch as above causes the motor to run audibly once again and to pull the hook to its closed (inward) position, as shown in my "new" latch at the top of the photo. Also attached is a photo of the bottom of the stainless steel sill plate, with its little hinged cover, which covers the striker plate and which must be removed to access it. In fact, removal is necessary just to see that there is actually a striker plate assembly, and not just a hook, beneath. Visible on the photo are four white plastic pins which engage female counterparts on the sill, and which simply pop apart . . . if one knows where they are, and where to pry. Looking at the top of the stainless steel plate gives (almost) no hint; only after one has removed the plate does one see two tiny pinch weld marks at the location of the cross braces and pins shown in the photo. These mark the locations where I found I was able to insert pry bar(s) beneath the rear edge of the plate (top of photo) and pop the plate off. Thank you, Bigbuzuki, and good luck to the next pilgrim!1 point

-

1 point

-

Parts required: ( I did this as inexpensive as possible) Steel tow bumper bought on ebay (200bucks) 955-618-040-10 Control Unit 955-612-506-00 Wiring Harness PNA-955-118-93 Trailer Hitch Connector (this is the 7 pin Pollak connector) PNA 955-127-08 7-4 way Adapter N-909-892-01 bumper bolts (8) Tools required: Allen key set 10mm wrench screw driver 1/4" ratchet torx driver set flashlight 21mm socket torque wrench Step 1: Remove spare tire floor by pulling hatch out towards the rear. There are no bolts that hold this in. Step 2: Use the torx bits to remove the chrome tie downs on the passenger side as well as the bolt closest to the hatch Step 3: After removing the side carpeted piece, there will be two additional screws underneath that hold the vertical carpeting piece in Step 4: Remove pillar cover on passenger side. Pull plastic cover labeled "airbag" off and remove screw underneath. Carelly work cover free at the top first. Step 5: Remove the exposed screw on the lower portion of the pillar Step 6: Disconnect trunk light Step 7: Remove the passenger side net anchor screws Step 8: Pull the passenger side section down. The clips are very tight, so be careful when prying the plastic. This is where the clip locations are. Step 9: Slowly pry passenger side pillar cover off, starting at the top. Once you reach the speaker, be sure to disconnect the wire as shown. Step 10: Remove screw that is now exposed on the rear pillar Step 11: Carefully pull the passenger side carpet panel out as shown. Step 12: Use the flashlight and look in between the carpet panel and the inner fender well. Pull out the pre-located harness plug, roughly half way in towards the front as shown. The plug is RED Step 13: Pull out and connect to the module. Plugs are specific so it will only fit into the center plug. Leave hanging for later use. Step 14: Remove both tail light allen bolts on the inside of the hatch area. They will be covered by two plastic plugs as seen below. Step 15: Carefully pry tail lights straight out towards the rear. There are 2 clips, one forward, and one rear on each lense. Disconnect harness and set aside. Step 16: Remove both torx screws on the bumper cover that were previously under the tail lights Step 17: In each fender well, remove the torx screws, starting in the rear, moving to the top of the fender. No need to remove all of them, you just need to access a hidden screw under the fender liner. Step 18: Remove hidden screw on both sides in the fender well. This is somewhat difficult to access, the torx bit will be FACING towards the rear of the car, close to the 10 o'clock position in the fender well. Step 19: Remove the lower allen bolts in the bumper cover Step 20: carefully wiggle the bumper cover free. The parking assist sensors will still be plugged in, so don't completely remove. Once far enough out, locate and disconnect plug on the DRIVER side Step 21: Remove foam and sensors as one, and save for reinstall. Loosen 8 bolts holding on aluminum bumper and completely remove bumper. Step 22: Install new STEEL bumper with hitch. Torque bolts to 140 lb/ft Step 23: Reinstall parking sensors and foam on top Step 24: Install plug cover into harness Step 25: Remove plastic cover on bumper support, and use screws to attach harness and plug assembly. Step 26: Route harness along the bottom of the bumper support towards passenger side. Remove rubber grommet and replace with grommet already attached to the wire harness. The wire ties should be positioned perfectly to install in holes in the bumper support. Step 27: Grab harness on the interior side, and route up and over the factory cd changer to the existing plug you found early on. Plug into module. Step 28: Using screws, install module on top of existing electronics in passenger side area. There will only be 2 plugs even though there are three sockets on the module Step 29: On the bumper cover, there are marking where to cut the relief for the receiver as shown below. I made the cut with a sharp razor blade Step 30: Reinstall all components and panels in reverse order (have fun with all of this!) Step 31: Locate the right fuse box on the side of the passenger side dashboard. Install a 15A fuse in slot 1, 3, and 5 plus replace slot 19 with a 30A. FINAL STEP: IF YOU ARE LUCKY, the module ordered is already programmed for the US. Unfortunately, it seems like the dealerships are stocking the UK version. You will need someone with a porsche scan tool to reset the module to the US version (UK is the fold out version). If you don't have any errors on your dashboard, then you have the right US version. If you get a tow warning, you will need the module reset. ENJOY!!1 point

-

Hey great DYI. Can you tell me how you got the beauty ring to move? Mines in the 1 o'clock too. Thanks.1 point

-

Here you go all the servo motors - check your options to make sure you get the correct one(s). 04cayenne_servo_motors.pdf1 point

-

Helen: The "temperamental" nature of the problem that you describe points to either bad/degraded connections at a number of possible points, or a hairline crack at the parallel strips microswitch inside of the convertible top latch assembly or a deformed plunger-type microswitch, also inside that latch assembly. You must first verify that the parking brake light on the dashboard is actually lit up when you pull up on the parking brake. Then double check that your fuses at B6 (supplies power to the convertible top double relay) and at D3 (supplies power to the convertible top motor) are intact AND that there is no corrosion at their respective spades on at the female receptacles on the fuse panel into which they are pressed. You can clean up any corrosion in those areas with a small piece of fine emery cloth. Next, double check for and clean up any corrosion on all of the male spades of the convertible top double relay, and the same for the female receptacles in the relay tray that accept the double relay spades. You can also tap the double relay on the ground a couple of times sharply, as that sometimes "revives" a sticking relay. If you have done all of the above and still get no reaction at all, you can then move to the convertible top latch assembly and its two microswitches. When you unlatch the top, the latch releases the plunger type microswitch inside the latch assembly and that causes it to ground. When it is grounded, a signal is sent to drop the windows about 4 inches. Poke your finger or a pencil eraser into that depression in the latch assembly and see if you get any reaction from the windows. If you don't, you will have to open up the latch assembly to access the two microswitches. Try the above steps first and report back. If there is no improvement, we can proceed with instructions on how to remove the latch assembly, etc... Regards, Maurice.1 point

-

On occasion during the most humid months of the year, the air coming out of the vents of my nearly 8-year-old car would smell a little 'off.' Since the a/c condensation was draining just fine and the odor wasn't ever-present, it wasn't a major concern to me. However, surfing the web I found a variety of A/C refresh kits that seemed worth a try, if for no reason other than to experiment and see if it was any benefit. But, no good deed goes unpunished. There are a variety of kits out there, some seem OE but most are aftermarket. I found them to have so much in common that I began to think they were made by only one or two manufacturers. The kits I was considering are two products: 1) a foaming spray that you inject into the evaporator housing through the condensation drain, and 2) a spray that you empty into the external air intake while changing the HVAC settings. The kits state or imply that they will clean the evaporator of crud that comes from dirt, mold, mildew, etc. and kill whatever causes odors in the venting. As I mentioned, the kits seemed nearly identical to each other so I bought one based on convenience at a local parts supplier for about $18. For another point of reference, there is a Toyota kit, part number 00289-ACRKT, that you can find here for instance. The product I used was the following: Note: This attempt to clean an HVAC system was for my particular 2003 986S. Other vehicles may be different and there are safety risks involved in doing mechanical or electrical work on a vehicle. What's presented here is a general overview of my DIY project, not a complete step-by-step set of instructions. Please obtain, understand, and follow the necessary repair and installation procedures in order to work safely, avoid damaging anything, and achieve a safe result. Preparation steps: I raised the vehicle up onto four(4) jack stands. Then I loosened or removed numerous underbody panels to expose the area under the passenger side floor pan. The location of the condensation drain is identified by an arrow in the photo below: First use the larger can of "evaporator foaming cleaner." You can read the instructions on the can in one of the photos above. I had to use another piece of tubing between the tapered nozzle and the condensation drain because the drain tube is not flexible and wouldn't hold the nozzle. That should have been the first indication to stop. Notice the grommet around the drain tube in the photo above and how the tube is inconveniently situated between the hot water supply/return for the heater core. As I was trying to force the tubing onto the drain, I pushed the drain tube and grommet into the passenger compartment. I knew it was going to be a pain to put it back, and it was. I had to remove the umbrella trim along the passenger-side door threshold, loosen the floor carpeting, and shove my arm under the carpet to reinstall it. Photos of the attachment and foam injection below: The foam went in, it seemed to sit for a while, it liquefied a bit, and then it drained out. The photo below was taken at a moment just as it was starting to drain: The liquid in the bucket was mostly clear, with a little particulate matter--nothing worth photographing. It didn't have much of a smell; it was slightly medicinal, like disinfectant. Following the instructions on the can, the next step is to use the "a/c intake refresher." Take out the pollen filter and spray into the air intake. You are supposed to change the vent settings between spraying intervals so that the mist runs through different duct work. Again, it has a slight disinfectant smell--pleasant but not flowery and not too strong. Not too bad, right?... Well, I was too preoccupied with the camera to realize what was happening inside the car: After all the effort for something that wasn't really necessary… I had to laugh. I was doing this process as I was preparing the car for winter storage. It was about 40° F (4° C) in my garage. Obviously, a lot of the foam didn't liquefy and drain. If I were to do this again, I would warm up the HVAC system beforehand, or just do the whole process at a higher ambient temperature. I'd also let the evaporator core drain longer (a lot longer) before doing the 2nd can. The photos above are the worst of it; only a little came out of the other vents. I blasted the system for a long time after that and it cleaned up without a problem--no damage to any surfaces. A few days ago I fired up the car for the season. No issues. Live and learn and pass it on. --Brian1 point

-

Please recommend a low profile, light weight, easily stored - floor jack. Thank you1 point

-

Here is how you replace the spring in the center console on a 2006 997S. The cost of the part was 87 cents. Here is a picture of the part. You remove eight torx screws to get the cover off. This is the cover off. Here is the cover. There were two different length screws but it does not matter where they go. Next you release tension on the spring. I have a torx socket resting on the spring release. The last step is to pull the hinge pin out. I used a vice grip and it worked real nice. Replace the spring and reassemble. This is a very easy task with a difficulty index of 1. I replaced the spring because the console door would rattle over bumps. The new spring works like a champ. Paul1 point

-

1 point

-

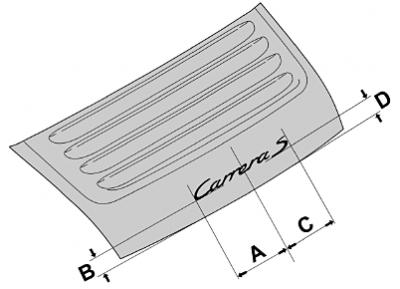

997 1. Find the middle of the lid. 2. Position logo Carrera with the dimensions A and C Carrera logo dimension 129.6 mm+/−1 mm and B Carrera logo dimension 45 mm−1 mm and stick on lid. 997S 1. Find the middle of the lid. 2. Position logo Carrera with the dimensions A Carrera S logo dimension 175.6 mm+/−1 mm and B Carrera S logo distance 45 mm−1 mm and stick on lid. 3. Position logo S with the dimensions C Carrera S logo dimension 175.6 mm+/−1 mm and D Carrera S logo distance 39 mm+/−1 mm and stick on rear lid. 9974S 1. Find the middle of the lid. 2. Position logo Carrera with the dimensions A Dimension: 175.6 mm +/-1 mm and B distance: 45 mm -1 mm and stick on lid. 3. Position logo 4 with the dimensions C Dimension: 19 mm +/-1 mm and D Dimension: 2 mm +/-1 mm and stick on rear lid. 4. Position logo S with the dimensions E Dimension: 190 mm +/-1 mm and F Dimension: 3 mm and stick on rear lid.1 point

-

If your battery is dead and you need to get into the front trunk, it may be necessary to locate the manual pull wire to open the front trunk and get to the battery. This might be more difficult to locate the first time. You may not be in a good location to wrestle the right front tire splash guard to find it. It might be night time or you may not be dressed in the correct clothes to be down by the tires trying to locate it. I would recommend that you take the time to locate it in good weather and in the comfort of your garage or better yet re-route the wire to the front bumper behind the plastic plug the hides the location for the tow fish eye bolt. To get started I removed the carpet liner in the front trunk. The front trunk liner is made up of 2 sections and I only had to remove the front section. There was one thumbscrew clip on the passenger side and one thumbscrew clip opposite on the driver's side. Also on the driver's side there was one snapin clip and 2 additional snapin clips located in the front of the trunk. All five clips are very easy to find and remove. I then removed the plastic trim directly on top of the front trunk latch and microswitch. There are 4 screw plugs and you simply turn the plastic plugs 1/4 to 1/2 of a turn: I then removed the passenger side head lamp by using the tool in the Boxster tool kit. The kit is usually located near the spare tire in the front trunk. Turn the wrentch about 1/2 turn counter clockwise to unlock the headlamp. Slide the head lamp out. You may have to jiggle it a little but it should slide out with very little effort. Once the light is out you will be able to locate the pull wire. It is clamped into a lasso at the end. In the photo below you can see it at the end of the red arrow. The red oval in the top of the photo is the plastic wheel splash guard. The passenger front tire is directly behind that. Some recommend to access the pull wire from the tire side but that is a little more difficult and you still have the problem of trying to re-rout the wire up to the front bumber. Doing it from the head lamp side makes it easy. Here is another photo with my finger pointing at the pull wire. Remove the front bumper plastic cover that hides the tow plug. I used a plastic upholstery tool and the plastic cap popped right out. The plug has a fishline wire connected to it to prevent you from losing it. Use the light from a flashlight to guide you (from the front bumber side) and re-route the pull wire from the headlight to the tow plug. Having the top plastic guard off makes this very easy. Tuck the pull wire back in and re-insert the pastic bumber plug. Reassembly is just the reverse. Slide the headlamp back into the guides and push it home, use the wrentch and turn clock wise. you will hear a loud pop when the headlamp is secured. You know have easy access to the emergency pull wire.1 point

-

Because of the demand for disassembling sun visor - here it is: 1. Unclip mirror insert 3 -- Insert a narrow screwdriver between the mirror insert 3 and the mirror housing 2 at the bottom center, and unclip the mirror insert. 2. Remove mirror insert 3 -- Pull the mirror insert 3 upwards and remove from the mirror housing 2. 3. Remove bulb 5 and contact clips 4 -- Remove the 12V /3W bulb 5 from the contact clip 4. Take the contact clips upwards out of the holder. 4. Unclip mirror housing 2 -- Insert a narrow plastic spatula between the mirror housing 2 and the sun visor 1 on the left and right and unclip the mirror housing. 5. Remove mirror housing -- Take the electric lead out of the mirror housing 2 and detach the mirror housing from the sun visor.1 point

-

There is no such thing as lifetime antifreeze. The fluid may last a lifetime, but not the **** in the coolin. system. Changing it every 3 years of so is highly recommended to flush out al the crap.1 point

-

The coolant container use to have Elf on it then Arteco, due to name change. Now the only name on it is Porsche. Arteco is a joint venture b/w Texaco and the euro chemical company Elf that was entered into in 1998 according to their website. I asked US Chevron/Texaco several years ago if I could buy an equal product at any normal car parts place. Chevron contaced europe. Havoline and Chevron Dex-Cool extended life meets the requirements of Porsche but "are not yet approved." This is the email response I received. "Subject: RE: Coolant for Porsche Boxster Date: Mon, 21 Oct 2002 06:07:47 -0700 From: "Dusing, William N" To: "'Jeff Lopez'" Jeff, The ChevronTexaco products in the US that meet the performance requirements of Porsche, but not yet approved are as follows: Havoline® DEX-COOL® Extended Life Anti-Freeze/Coolant Chevron DEX-COOL® Extended Life Antifreeze/Coolant Hope this helps! Thanks, Bill" Like Porsche is ever going to approve something something I can buy at any parts place for a fraction of the cost. I am on one of the UK Boxster boards. In the UK Mobil sells a coolant approved by Porsche. Do not think Mobil sells coolant in the US. Guess Mobil got the approval because they already pay Porsche for the Mobil 1 sticker under the rear lid. :rolleyes:1 point

-0001-0001.thumb.png.17f5bb25bf8ec261a17c21e6321c8492.png)