Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

Leaderboard

Popular Content

Showing content with the highest reputation since 06/04/2010 in all areas

-

Does anybody has this problem with their horns? Basically, if I go over a bump, or stop on a slope, the horn will turn on. It is very annoying especially people in front of you thought your are hornking at them. Any advise, will be helpful. Thanks, -Nat31 points

-

This is a continuation from the front wheel bearing change. That was good practice for the rear of your car. Although i thought the rear was more difficult than the front but after i was done and found a couple of tricks that i will share, it might actually be easier. Having the right tools always make things go smoother. The B90-P2 tool i bought at http://www.samstagsales.com/Porsche.htm#axle Took only 3 days to get it. I was away at work for 4 days so the timing was perfect. Great service. Earlier this year people were wondering where to get the tools to take apart the electrical connectors. Well sams tag sales has all the Porsche tools needed. With the SIR TOOLS kit they sent me the catalog with all the speciality stuff. If you don't have an arsenal of basic tools i would recommend going to Sears. The prices are higher than a China Freight but Sears does treat their people well and nothing like supporting the american people right? Attached is a photo of a great tool set that has almost all that you need. It even comes with the 32mm large socket for the hub bolt. Aside from those tools you will need some larger wrenches. 21mm for the track arm. (Actually you don't have to take this apart...more later) But you do need some larger wrenches for the Sir Tools Kit. 1 and 1/16. Some allen key sockets. Best to get a set of 7 in metric. Sears also sells the Torx socket set too. You will need at least 2 torque wrenches. My trick for the 360 foot pound setting is later. Some plyers, punch, screwdriver set. Phillops, flat etc... Discount auto parts sells a paint can full of GunK degreaser. And has a tin to put the small bolts in. Great stuff. Don't drink it. If i forgot some i will post it further down. So lets get going... Have the car parked so you have lots of space to work around it. Back the car into the garage far enough so you have room to close the garage door if you need to make a run to the tool store. Don't ask me why i mention this! Set the parking brake, and remove the center cap. I pushed in an allen key and used a vice grip to pull it out. Pull hard. Get your long 4 foot bar, 32mm socket and loosen the axel bolt. You can even take it off all the way, it doesn't reall matter. Loosen the 5 lug bolts, 4 19mm and the third i hope you have the locking one. Jack the car up and put it up on stands. You will need to use the jack later and it just isn't safe to have your head under a car with just a hydraulic jack. Remove the wheel bolts and then the wheel, don't forget to use the factory supplied tool to help with the removal and installation of the wheel.30 points

-

Finally got around to doing the front wheel bearings on my 1999 Boxster. I bought the SIR Tools B-90 P2 kit. $259.00 Bearing seperator from China Freight $29.99 (ON Sale) Craftsman 32mm large socket. $11.99 4 foot bar extension or pipe. (Home Depot $10) Bearings from, I can't remember but a while back. $30ea Jack Stands Jack Important Anti Seize Compound $8.99 (NAPA) Large wrench set. Sears $59.99 (I kinda went overboard on the wrenches. They had them on sale and even thought Craftsman is a lot more than China freight they treat their employees well, i think they are made in the USA and we need to support American companies, my .o2) Various other tools sockets, punch, spring compressor etc...You will see as i go along. So first off is to open the front trunk and get out two tools. The wheel lock key and the wheel post. Start off with taking the center cap off the wheel while it is still on the ground. Take the 32 mm socket and loosen the big center bolt. You will need to use a large ratchet, small extension and stick the home depot bar on the end. Be careful to use a quality ratchet or it might break and you will be doing some paint work later. I had taken the steel bar and pounded it into an oval shape so it would fit overtop of the ratchet. This bolt is tight so make sure you have the parking brake on. Next loosen the wheel bolts and jack the car up. Take out one bolt then put the alloy peg in one of the holes. This helps line everything up and keep the wheel from falling onto your nice painted caliper. You should have the wheel off and put somewhere out of the way...You won't be needing that anymore...At least for a while. On the front of the rotor there are two phillops screws. I like to remove them now as the brake pads are holding the rotor from spinning. You may need a special tool to get these out if they are stuck. Just be careful not to strip them.28 points

-

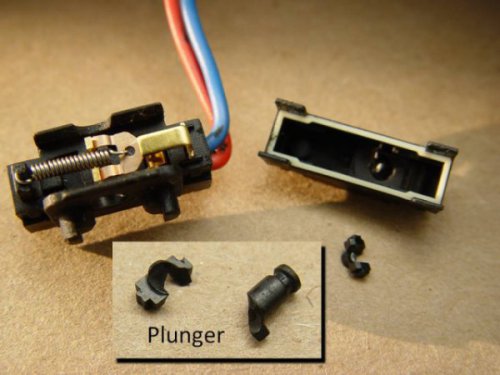

It seems that there are more and more cases of these faults appearing, and as some of our cars are reaching 10-12 years old, it is hardly surprising. I've compiled this information from past personal experience on both of my 996s, reading about others on here and other forums, referring to the workshop manual and wiring diagrams, and applying some logic. Hopefully you might find it useful, and save some grief when troubleshooting. DOOR MICROSWITCHES There are seven microswitches in each door which control the alarm system. Two are separate switches: a] One on the outside door handle. This switch is used to sense that the handle is lifted. b] One on the inside door handle, which has the same function. When the car is unlocked and either handle is lifted, this signals the alarm control module (ACM) to lower the appropriate window by 10mm, and turn on the interior lights. As soon as the door opens, another switch inside the door lock (explained later) tells the ACM that the door is open, which holds the window down until the door is closed, when the window is raised, and the dimming timer on the interior lights is started. Once the car is locked, the outside handle switches are ignored by the ACM. The remaining five switches are inside the door lock assembly: c] One switch senses if the door is open or closed. d] One senses that the key has been turned to the 'lock' position. e] Another senses that the key has been turned to the 'unlock' position. f] One senses that the door lock motor has reached the 'lock' position. g] Another senses that the door lock motor has reached the 'unlock' position. TYPICAL FAULTS All these microswitches can be problematic, and it is common for one or more to fail at some time. These are some of the common failures and symptoms: 1) The door window won't drop when lifting a handle. This is usually the handle microswitch which has failed. 2) The window drops, but goes back up when the door opens, or when the handle is released. This can be the handle microswitch, or more likely the 'door open/closed microswitch' ( c ) has stuck. Because the system thinks the door is still closed, it sends the window back up. 3) Door window won't go up the last 10mm. This is likely to be the 'door open/closed microswitch' ( c ) stuck in the opposite sense to (2). The system thinks the door is still open, so won't allow the window to go back up. Note that in this case the door will still lock, but you may get a single-beep from the alarm horn. 4) Door will not lock with key. The 'key lock' microswitch (d) is broken. This is very rare, as this microswitch is hardly ever used – most times the car is locked by remote. 5) Door will not unlock with key. The 'key lock' microswitch (e) is broken. This is also very rare, for the same reason. 6) Door locks, and then immediately unlocks, usually accompanied by a double-beep from the alarm horn. This is the 'door locked' microswitch (f). The locking motor physically operates the door lock, but the microswitch to sense this has failed/stuck. The ACM promptly unlocks the car. In this case, the only way to lock the door is to use the emergency locking procedure. Turn the key in the door to the lock position and back three times in quick succession. 7) The door unlocks, but there is a beep or double-beep from the alarm horn. This is the 'door unlocked' microswitch (g). Although the door is unlocked, the ACM has not recognised that. The alarm will not sound, as turning the key in the lock has deactivated it. FIXES The inside and outside handle microswitches are available separately, and are not too expensive. Although alternative equivalent switches may be available, the genuine Porsche switch comes with a connector and wiring, so it makes sense to use an original. Part Numbers: Inside handle microswitch: 996.613.123.00 (Same both sides) Outside handle microswitch: 996.613.125.00 (Left) / 996.613.126.00 (Right) The door lock microswitches are not available separately. You have to buy the complete door lock assembly, at a cost of around $120. It has been known for people to repair the offending switch though. This is a picture of a typical failure of a 'door open/close' microswitch (courtesy of another RennTech member): You can see that the plastic plunger has broken, jamming the switch lever inside. These switches are (apparently) made by Burgess, but as yet the source and part number are unknown. There are several other similar standard switches on the market for around $2, and people have stripped down the new switch and rebuilt the old one with the plunger from the new one. OTHER SWITCHES IN THE ALARM SYSTEM The other switches and contacts in the alarm system are to monitor the lid closures: Front lid microswitch Rear lid microswitch Oddment compartment microswitch Glove box microswitch Radio contact (to detect radio theft) An open compartment or switch failure will cause a single-beep of the alarm horn on locking. A system error will cause a double-beep. Other elements of the system include an interior monitoring sensor (in the overhead lighting), an alarm readiness light (on the dashboard in the centre) and a central locking button (on the dashboard). Options are a tilt sensor (next to the battery or under the left-hand seat) and an alarm siren (next to the battery).27 points

-

First off - thanks to everyone who has been down this road before me for providing tips and suggestions and troubleshooting regarding this common problem. I have been dealing with a key that would stay all the way to the right upon starting meaning that the A/C, heated seats and some other items would not function. My solution had been to simply start the car and then just move the key back one notch to the left and everything worked fine. So if others have that issue, my original solution will work but obviously the problem remains and at some point you may end up stranded if the ignition switch completely fails. I stumbled upon some of the other threads and found that this needed fixing and I opted to replace just the switch as opposed to upgrading to the new complete unit that Porsche has moved to. This procedure is not new to the board, but I thought a step by step with pictures may be useful to those looking for an inexpensive solution. It cost me $12.11 including tax. If your ignition mechanism has been changed to the newer revised unit the ignition switch is a different part number but I assume the steps would be the same. The part for just the switch - no longer available through Porsche since they are only selling the entire $150 unit - is 4A0905849B. The switch alone is available mail order through Pelican for $10, Autohausaz.com was +/- $8.75, Ebay has them all over the map from $15-30. All of these options will work but require shipping charges and delivery time. I was hoping for a local option since I had the time to do it today. Here is what I found in Houston - a local Audi dealer had one in stock for $35, while VW had to order it (for more than $35 believe it or not). Doing a search online at parts stores using my Porsche got me nowhere so I opted to use an older Audi - in my case a 1997 Audi A8 since the part is the same. I found Autozone had one for >$40, OReilly came up blank but I did not call to check, a specialty imports place had one for $27 and then I found it in stock at NAPA for $11.19 + tax. Since NAPA seems to have stores all over the place I suggest looking there first if you don't feel like mail order. The complete part number at NAPA was ATM 4A0905849B using the 1997 Audi A8 as the vehicle. Here is a picture of the NAPA part (left) alongside the original part which I removed from my 996 cab - note the AUDI rings on the old part. Equipment needed: Small flat screwdriver - eyeglass or electronics size Philips screwdriver Torx driver 10mm wrench rubber pry tool Cold beer to celebrate 1) Disconnect the battery - I just undid the negative with a 10mm wrench 2) OPTIONAL but makes the job easier than the shop manual in my opinion. Remove the side air vent by pulling the headlight switch towards you and inserting a small blade screwdriver up from the six o'clock position. You should notice a spring like resistance which will release the knob and allow it to pull towards you. Here is a picture of the back of the knob showing the release mechanism Once the knob is off remove the three torx screws – one in the headlight control recess and two on the side After the screws are out take a rubber pry tool (or be careful with a flat screwdriver) and remove the vent housing - it will pull towards you with a little effort but not much. Once off I pulled it out far enough to gain access but left the headlight control connected because I was lazy and saw no need to unhook it. I forgot to take a picture of this part but it should be self explanatory. You will now see a philips screw directly in the back of the air vent - remove. 3) Crawl under the dash and remove the center piece (A) of the air vent - there is not much room and you will not miss it. The piece can be nudged towards the side to release on one end and then the other. Since you removed the screw from above you should be able to remove the middle and side piece now out the bottom. 4) Unplug switch by pulling directly off the back - do not unhook the purple tabs just pull the entire unit back. Make sure to pull this off BEFORE unscrewing and removing the switch as the screws holding the switch in make this much easier than trying to get a hand in there - believe me I jumped ahead and then resorted to screwing it back in. 5) Unscrew two set screws - one on the bottom on one on the opposite side. The screws are coated with red paint that may need to be chipped through with your screwdriver before you can get the screw to grab. I unscrewed the bottom screw while under the dash and then from the seat I reached under and could view the top screw through the side vent area and unscrewed it. Do not remove the screws just undo them far enough to remove the ignition switch. Bottom screw noted in this picture Top screw as viewed from side vent opening - this can also be done from underneath but the small space and clutch pedal against my head led me to look for easier access 6) Now that the screws are loose you should be able to pull the ignition switch out and replace it with the new one. Screw in the set screws, hook the harness back to it and get ready for a cold beer - not quite but almost 7) Slide out from under the foot well, hook up the battery and see if all is well. You may as well check before reattaching the rest. If the car starts as it should you will notice a nice smooth ignition with the slight spring back to the left just after ignition. Hook up the air vents, screw everything back together and push the headlight knob back in place 😎 Crack open a cold beer and smile - you just saved a lot of money. This is one of the simplest "repair" DIY out there - it took me probably less than 20 minutes including removing the side vent and I took my time since I had never done it before. If I need to replace it again - which is likely - it will be even quicker. You can always replace the entire ignition module with the new and improved unit at around $150 I think - and alot more effort - but for $12 and 20 minutes I am hoping I can get some decent life out of this switch and then just replace it again in a few years if I need to. Like I said before - this is not a new DIY but I am hopeful that these pictures will be helpful. Thanks again to all of those who provided the prior posts.26 points

-

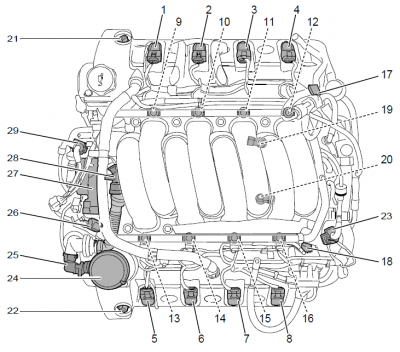

Note: Part numbers sometimes change without notice. Always double check with your supplier that you have the latest part numbers. Parts you will need: 6 ea 999 170 207 91 Spark Plugs (Beru 14FGR 6KQU) MY99-MY01 or 6 ea 999 170 223 90 Spark Plugs (Beru FGR 5KQE0) MY02 Tools you will need: Jack 19 mm socket for wheel bolts Snap-On S9706 Spark Plug Socket Snap-On FXW4 (4 inch) Extension (or any 3/8" drive extension that allows at least 16 degrees of offcenter movement) 3/8" Ratchet 5 mm hex allen socket or 5 mm allen wrench Torque wrench Note: Most find that removing the muffler first (a 15 minute job) will make spark plug replacement much much easier (and faster). Jack up the vehicle at the lift points provided and remove the rear wheel (you will need to do this for each side).<br></li><li>Remove the 2 fastening screws (M6 x 20) of the shields on the cylinder heads and remove the plates. Disconnect connection cable of the ignition coils. Check for damage and replace if needed Remove the two fastening screws (M6 x 25) of the plug coils and remove the 6 plug coils. You may find it easier to remove the top 5 MM socket cap screws first. Then remove the bottom screws. Unscrew the spark plugs using the spark-plug wrench. Remove the spark plug and install the new plug by hand. Do not use any anti-seize or any other lubricant on the plug threads! Use the socket extension minus the ratchet to get the plug started. Always turn the plug counterclockwise until you feel it seat. This insures that the plug is in the threads on the cylinder head so there is no concern about cross threading it. Then turn it clockwise until it is as tight as I can get it by hand. IF YOU CAN'T TURN IT BY HAND THEN IT IS NOT THREADED PROPERLY When the plugs are hand tightened, attach the ratchet and tighten it a little. Then use the torque wrench to finish the job. Tighten new spark plugs to 22 ft-lb. Push on plug coils and tighten the fastening screws (M6 x 25) to 7.5 ft-lb. Reinstall the bottom screws first and then top. Subsequently push on the connecting cable of the plug coils. Refit the two shields and tighten the fastening screws to 7.5 ft-lb. Re-install the wheel(s) and lower vehicle. Torque the wheels bolts to 96 ftlb. (130 Nm)23 points

-

I recently replaced the coolant pipes in my car. I needed to do the job myself because there was simply no way I was going to shell out anywhere from $1500 to $3500 in labor to have it done by the dealership or an independent shop. Plus, having read about the job, I knew they would be tearing through a ton of stuff and I really feared the "oh, it also needs this" scam. I did a LOT of research on the various forums before undertaking this job. Reading and printing out anything I thought was useful information. I would highly encourage anyone reading this to do the same. Fortunately, I was not in the position that the pipes simply failed and dumped all of the coolant. I just had a semi-slow leak… dropping about a gallon of coolant every two to three weeks. So, I had time to order the parts and prepare. Prior to doing this the most complicated thing I had done myself was change the oil, replacing the brake pads and swapping out some plastic bits in the car. I had absolutely no prior mechanic experience whatsoever. However, I do work in IT, and am by nature a very technical person (I'm sure every mechanic reading this just rolled their eyes). My job is troubleshooting very complex problems on very large networks, and I think that experience probably lent itself to a successful outcome here. I'm also patient, and that is critical to getting this job done. I will say that I now have a much greater appreciation for mechanics and their skill set. This was hard. I want to caution anyone reading this that this is a BIG job and it will take a long time. My goal in writing this is so that my fellow Cayenne owners can be spared a lot of the mistakes I made and be better prepared than I was. I will say I am relieved to have this done. I feel a ton better about my car now that I don't need to worry as much about some catastrophic failure hitting me unexpectedly. One rule that I really appreciated was to only place metal on metal when working (until you actually get to removing the pipes). This prevents you from breaking plastic or tearing rubber with something metal. Trust me, pay attention to that rule. I am breaking this down into tasks, because I think it's easier to follow that way. This is how I did it. I am sure there are other ways that may even be easier, but this worked for me and my schedule. I ended up working 4-6 hours at a stretch in the garage with breaks every couple of hours. Step 1: Contribute to this forum I have absolutely no affiliation with this forum whatsoever other than I am a contributing member. The advice on this forum has personally saved me thousands of dollars, and being in IT I know the time and money it takes to run a site like this. So, contribute to the cause. However, there is a second reason to contribute, and that's to get the Porsche TSBs. The TSB for this job contains some diagrams that give you a better idea how all the replacement parts go in to place, and I thought that was handy to have. As an aside, I searched some other issues in the TSBs and found answers to some things the dealership didn't even know… such as there being a $33 replacement latch for my armrest. They wanted to sell me a whole new armrest for $750. Step 2: Obtain the Parts I looked around on the Internet and called some local sources and found a dealership that provided the parts for $550, and that included two gallons of coolant shipped to my door. To me, that was a fair price, and when I received the parts I really thought it was a fair price... there's a lot of quality stuff in there. I'm sure there may be cheaper 3rd party sources. I would just be sure they include all gaskets and such that don't necessarily need to be replaced, but should be replaced if you're tearing everything apart. Once you get the parts, pull them out of the box and examine them. Look at the pics in the forum and look at the TSBs. Get a feel for what you are replacing. Step 3: Verify you have the tools I found the following tools very handy to have, and frankly, necessary. I suggest going to your local auto parts store for most of them and get mechanic grade tools. Socket Wrench 3" Socket Extension 6" Socket Extension Metric Socket Set Torx Socket Set (think of this as a "male" Torx Socket set, you will need #27 & #40) E-Torx Socket Set (think of this a "female" Torx Socket set) Screwdriver that accepts interchangeable bits (there are times this is easier than a socket wrench) Torx Bit Set (Specifically you need a #27 and #40, I just bought a set) Locking Long Nose Pliers (6" is fine, no need for anything bigger) Regular set of pliers Wrench Set (somewhat optional) Real flat head screwdrivers Very long flat head screwdriver (this came in handy a lot) Needle Nose Pliers Small Chisel Set Hammer Tin snips Safety Glasses Mechanics Gloves One of those extension things with a magnet on the end One of those extension things with a mirror on the end WD-40 Some all-purpose grease, like White Lightning Baggies to store the screws in Masking tape/Painters Tape to cover up any exposed openings Old Bath Towels (used to protect the car) Good flashlight Lint free rags Shop Vac Two gallons of distilled water Drain pan (needs to hold 4 gallons) Shop lights A small block of wood, about 2" x 4" x ¾" A radio playing energetic music of your choice Advil and Tylenol Hope and a prayer (optional but doesn't hurt) Step 4: Book the Time I know some people say you can have this job done in less than 8 hours, but being a beginner this took me much longer. If I took out all the time running back and forth to the store for tools and such, and had a guide like the one I am writing, I still think it would have taken 10-12 hours. I ended up removing all of the engine covers on one weekend night, and then doing the actual job the following weekend. I then drove the car for a week with the new pipes and finally put all the engine covers back on over the weekend (I cleaned the covers and the engine thoroughly with a damp rag at the same time to pretty it up a bit). You don't really need to do it that way, but that split the work up a bit. I work in an office in front of a PC all day; I'm not used to working in a hot garage for 8-10 hours at a time... I'm a skinny computer geek : ) When I did the work, I draped some old bath towels over the sides and front of the car to protect it. The last thing I wanted to do was mess up the paint on a zipper or with a dropped tool/screw. Step 5: Remove the Engine Covers There are really two parts to this. You have the decorative covers over the actual engine, and then you have the covers that border the engine. You'll want to remove all of the covers around the border first. There are five of them in total. They all have these little black plastic plugs that you just turn 90 degrees. They should just pop up at that point, but you might have to give them a little lift with a screw driver. While you're removing those covers you might want to pay attention to how they go together and where they slide in to place. You'll also want to remove the windshield washing fluid cap (use the masking tape to cover up the exposed hole) before you remove the cover that surrounds it. Those little things are $4.25 each from the dealership, so try not to lose them. Now you have the three silver looking decorative covers; one on each side of the engine and one towards the front middle with the engine type on it. First, you need to unbolt the two secondary air injection units. Those are the round things with the plastic covers near the back of the engine compartment. You do not need to disconnect them from anything, just unbolt them (three screws each) and then move them off to the side. It might be a good idea to get some labeled baggies to store the screws in. Once those are removed you can get to the side engine covers a little easier. The engine cover in the front middle you just lift off, just work it back and forth a little and it should pop off. Take note that there are four little plugs that fit into holes on the cover itself, you'll need to find them again when replacing it. Now remove the one on the driver's side. It's pretty easy to remove. There are four screws towards the bottom that need to be removed, and then the cover will just come off. The one on the passenger side is a bit different. You have the engine mount right in the middle of things. Assuming you have the tools, you can unscrew the engine mount and get it out of the way. That will let you get to each of the four screws easily on the cover and remove it. I wasn't so lucky here (didn't have the right tools at the time), so I just got the four screws out of the cover and ended up wedging it out. While doing that, the piece of the cover under the engine mount snapped off. I wasn't too concerned about this, because where it snapped is hidden by the engine mount. When I put everything back together I just slid it back and screwed it in. You can't tell at all that it was ever snapped in half. Step 5a: Remove Fuel Pump Fuses You'll want to check your manual (you can also download the manual from this site), but you need to remove a couple of fuses for the fuel pump. Right in front of the driver under the hood there is a small compartment. Remove the cover, and then remove a second cover to expose the fuses. Mine were fuse 14 & 15 for the fuel pump. Store them somewhere safe. Once those are removed, start your car. It will run for a few seconds and die. Congrats, you just removed most of the fuel from the fuel line. I know some people don't disconnect the fuel rail or anything, but to me that's a bad idea. I had a lot of time to try it that way and honestly I'm glad I got it out of the way. Step 6: Disconnect the fuel line The fuel line is near the back center, it's just one tube running to the fuel rail. You'll disconnect it by using a wrench and a pair of pliers. You're unscrewing the part on the left (the thin part) from the part on the right (the wide part) which shouldn't turn as it is part of that tube. Once unscrewed, the fuel rail is only connected to the manifold. A little residual fuel might leak out, so you might want to have a rag handy to wipe it up with. Use masking tape to cover up any exposed holes. It wouldn't be a bad idea to disconnect the batteries now either. I didn't, but that was probably stupid. Step 7: Remove the Y-Pipe that goes to the Throttle Body This plastic Y-Pipe is right up front so it's very easy to get to. There are two flexible pipes on either side you need to remove first; just use a screwdriver to loosen the two clamps on each of them and you should be able to compress them enough to remove them. The Y-Pipe itself is attached to the throttle body via two long, plastic bolts. They have a screw head on them but they are not screws, they're more of a key. You just turn them a bit to line the key at the bottom (use a flashlight and you'll see it move as you turn it with the screwdriver) with the slot. When it's lined up, use a pair of needle nose pillars to lift it straight out. It's plastic and may be brittle, so be a little careful. You will need to remove an electric connection to the throttle body in order to get to one of them. There is a tube connected to the bottom of this y-pipe, so you can't just lift it out. It has some give to it, but not a lot… just enough to get your hand under there once you pull the y-pipe off the throttle body. You have to press the buttons on each side of the tube in order to get it off the y-pipe. Step 8: Remove Emission Tubes & Electrical Connections from Throttle Body There are two emission tubes crossing the throttle body, Porsche refers to them as "vent tubes." I know this because one snapped in half when I removed it, and the dang thing was $130 to replace. To remove them, you just need to press the clips at either side of the end of the tube together and then pull it straight out. I don't think mine had ever been removed, and in retrospect a bit of WD-40 used sparingly here might have been a good idea. I think I used too much force and that's why the small one snapped. I have read that some people have replaced this broken tube with a more generic tube from a hardware store. I just spent the $130 and did it right. There is a third tube connected to the throttle body, you just need to remove that one end of it. You will also have two electrical connections to remove. One you had to remove to get the y-pipe off in the previous step. Just remove the second one and then you're done. Step 9: Remove the Throttle Body The throttle body is connected to the manifold via four bolts. Remove those four bolts and it will come off. You sort of have to wiggle it out because of that thin metal bracket that's holding it there, but it will come out easy enough. Some people take this opportunity to clean it. You'll probably see some gunk on the back side of it on the inside. Step 9: Remove the Electrical Connections to the Fuel Injectors There are eight fuel injectors connected between the fuel rail and intake manifold. Mine were blue plastic, and there is an electrical connection running to each of them. There is a metal clip at the bottom that you just need to press up. I placed a flat head screwdriver between this clip and my index finger, and pushed up and pulled at the same time to disconnect it. Once you remove one you'll get the trick and the rest will come right off. Step 10: Remove the Intake Manifold with Fuel Rail Attached I know a lot of people have different ideas here, some people want to remove the fuel rail independently, and that was the first way I tried it. In retrospect, it's much easier to just leave it attached. There are four screws that hold the fuel rail to the intake manifold. I would recommend leaving these alone, especially since the one at the back on the passenger side is nearly impossible to get to. These screws are $6+ each… I know because I lost one. :P There are 10 bolts that need to be undone to remove the manifold. They don't come all the way out, they'll stay attached to the manifold. Once you loosen them enough they sort of come free and wiggle around. The one at the back on the passenger side was a bear to get to. I ended up placing the Torx Socket bit on top of it using the magnetic extension thing. I then put the 3" extension on top of it, and finally attached my socket wrench to it. I kind of built it all up I guess. I then went really, really slowly and loosened it up. Once loose, make sure to vacuum up any debris on the engine. When you pull the intake manifold off you will have eight gaping holes right down to your cylinders, you don't want anything falling in there. You can now scoot it forward a bit to get to the tubes you will need to disconnect. There are two tubes at the back of the manifold… a firm one and a flexible one. The firm one is just like the one under the y-pipe, and is easy enough to remove IF you can get enough pressure on the connector. The flexible one was just kind of stuck on mine and I left it on. You kind of have to scoot the manifold forward and angle it out, but it will come out with the fuel rail attached. You may have to remove some tubes and such from their guides or brackets. That flexible tube was long enough that I just put the whole thing on the driver's side of my engine and left it there. It didn't seem to be sitting on anything that couldn't support it. I'm sure it can be removed, but at this point in the job I was tired, hot, and just wanted to keep going. Once off, IMMEDIATELY cover up the exposed intake holes with long strips of tape. Cover them completely, and make sure they STAY COVERED. Shine a flashlight in each hole first to make sure nothing fell down there. If so, get it out as delicately as possible. Vacuum up any other debris you see. You can now see the infamous coolant pipes. Step 11: Assessment At this point, you can see the coolant pipes and should be ready for the meat of this repair. The starter is right there too… right under the leaking pipes. Brilliant, isn't it? This may not be true for you, but I had an AMAZING amount of debris in here… honestly looked like a bird had built a nest. I have no idea how it all got in there, but some where at some point tons of debris got in here, and now it was all soaked in coolant. I think my coolant leaking may have been mitigated because the wet debris probably acted as a mud and sealed everything up a bit. I vacuumed it up with a shop vac prepped for a wet cleanup. Now you need to decide if you will see this repair through or not. Once the next step is taken, there is no going back, and honestly the toughest part of this job by far is getting the old pipes out. Step 12: Drain the Remaining Coolant Your first goal is removing as much coolant from the car as you can. On the V8's, there is a drain plug at the bottom of the car, but on the turbo's you won't have one. That drain plug required an allen bit that was larger than I had on hand or could even find at a hardware store. Honestly, in retrospect I wouldn't have even bothered locating it. I'm sure there's a pipe down there you could remove, but I didn't waste time looking for. I took a tip I found on a forum, and drilled a hole right in the middle of the center coolant pipe (of three) and used a siphon with a hand pump to drain out every bit I could. I repeated this process on the larger lower pipe. DO NOT SIPHON BY USING YOUR MOUTH. Coolant is dangerous, nasty stuff. Make sure there are no animals or kids around while you are doing this. WEAR SAFETY GLASSES AT ALL TIMES! Doing it this way you're going to spill a lot of coolant, but it is what it is… they've been leaking all over everything anyway. I used my shop vac to vacuum up anything I could that escaped the siphon. I've also read of people renting professional vacuum pumps to suck it all out, but again, that's more complicated than it needs to be. I did some research, and coolant is not currently controlled by the EPA for disposal, and it can't be recycled. The unofficial advice I got was to dump it in the woods and douse the area with a hose for a bit. Do not dump it down the drain or dump it where animals could readily drink it. Don't dump it in a stream. Presumably it breaks down fast enough on the ground that there isn't a long lasting effect. Step 13: Remove the Three Upper Coolant Pipes The first pipe you need to remove is the long skinny pipe with three connectors. This one is easy enough to remove, and you should have a replacement as part of the kit. One of the connectors broke off in the hole, and I had to very carefully remove the pieces. Relatively speaking this was easy compared to the rest. There is a compression ring that needs to be removed for the connection at the back of the engine, use the locking pliers to do that. Cover up the exposed holes with masking tape. You now have to remove the three upper coolant pipes. There is a bracket at the back of the engine holding the three pipes. There are also two clips attached (you'll be looking at the back side of them) to that bracket that just support a hose at the back (just has electrical connections in it, and it's probably already split so you don't have to be super careful). Pinch the connectors with a pair of needle nose pliers and they'll come off. You now have to remove three bolts from it to remove the upper half of that bracket. I removed two of them but couldn't get to the third without snapping the thing in half. Porsche was kind enough to provide a new one in the kit so I wasn't worried about it. You will now see three rubber hoses attached to the plastic pipes. They are held on to them with compression rings. Use the locking pliers on the rings to loosen them (they need to be squeezed together to loosen) and slip them back over the pipes. I did one at a time, completely removing the ring and setting it off to the side for safety. The locking pliers really excelled here. When using them, attempt to come at the ring from the top instead of the side, the grooves on the pliers will then secure the ring quite nicely. You might have to adjust the pliers a couple of time to get the right amount of the compression for the ring to move freely. With those ends free, I used the shop vac to suck out a lot more coolant. Once done, cover up the exposed holes with masking tape. Once those three ends are free, you'll need to free up the other ends. Here's the deal, they are probably going to break when you try to remove them, and probably going to snap off at the spot where they connect to the coolant reservoir. I twisted and pulled and sure enough, they snapped off. You can remove the lid of the coolant reservoir by removing several screws, a small aluminum pipe on top, and the rubber pipes towards the front of the car. The small aluminum pipe has a single screw that needs to be removed. There is probably a lot of corrosion here so you may need to use a flat head screwdriver to pry it out. Be careful, it's flexible enough to come out and get out of the way but just barely. There is a compression ring on each of the rubber pipes that is easy enough to get to, just loosen and slide it down the pipe. Suck out any coolant and cover the exposed pipes with masking tape. Once you have that lid out, you'll see the remaining plastic bits in the holes. It's difficult to move, but those plastic bits are just in there with pressure, they aren't glued or anything. I used a small chisel and the hammer to break them out. As I got to the o-rings I pulled on those with needle nose pliers and in one instance the whole chunk came out. I also used a lot of WD-40 to work everything out. What you don't want to do is take any risk of chiseling into the metal of the lid, so be careful. This is all about removing the plastic material. Each bit you remove gets you one step closer to freeing up enough pressure to get the remaining bit out. Once it's all clean, leave it off to the side while removing the big pipe. Step 14: Removing The Big Pipe This one is tough. Make sure you're rested, well fed, and cooled down a bit. If you're aggravated already, walk away and relax a bit. You will need to break this pipe into two pieces. I used a boring bit to drill a big hole in the top, and then used tin snips to cut chunks out until I got it in two parts. Again, I used a shop vac to suck out any remaining coolant as I went along. Really, anything will work… you could even use a chisel to break it out. It's coming out one way or the other, no need to be pretty about it. Once it's in two pieces, you can probably rotate the two halves apart. Use WD-40 generously on the ends first though, and give it a bit to work in there. Regardless, when I went to pull out the two ends, they ended up snapping off… leaving their end pieces in the hole. If you read through the three forums, different people use different techniques to try and avoid this with mixed results. This is the worst case scenario though, so lucky for you I fought through it and have plenty of advice. Assuming your pipe broke off as mine did, you will see a metal ring in each end, with black plastic between it and your car. That metal ring was an inner support ring for the original pipe and needs to be removed. This is a violent procedure. IMPORTANT: I cut up some lint free cloths and stuffed one into each end as far as I could so that any material from the following procedure wouldn't go any further. Once done with the procedure below, I vacuumed up anything I could and then removed those cloths. Again, use WD40 a LOT. I sprayed and sprayed as a worked, and I think it helped. READ THIS CAREFULLY: Removing the plastic and metal ring from each end is all about removing material. You are trying to get as much plastic out as possible. If you get the ring out first, great, but it's not 100% necessary. The plastic is what needs to come out, and you need to get it out from all around it. In addition to the plastic, there are two o-rings in there, so they are just adding more friction preventing this from moving. You'll get bits of that out as you work, and that's good. Eventually, you get enough bits out that the rest will just fall out. Use a hammer and chisel to collapse the metal ring on the top and sides as much as possible. I used to the chisel to cut in to it a bit too. Once I got it that far, I switched to the long screwdriver, hammering the end of it into the plastic over, and over, and over again. I pried as much as I could and worked out bits of material. This took a long time, but sometimes you'll get a big chunk out and that will give you renewed hope. Again, this is all about material removal. Keep telling yourself that. Every bit you get out makes this easier. Once you get enough plastic out, you'll see the metal ring move a bit as you work. This is a great sign and you are almost done. Ultimately, you should be able to pry it out with the screwdriver. NOTE: When working you want to work as much towards the metal ring as possible. You want to avoid scraping the inside of the hole where your new pipes will go. I did scrape up mine a bit, it's unavoidable, but regardless my new pipes don't leak. When you go to remove the bits closest to you, you're working somewhat blind and it is hard. This part almost broke me, but I used a mirror to check and recheck my work as I went along. Bright lights help here too. Honestly, I really can't say enough how hard this part was and how long it took in comparison to everything else. It was the part that had me the most worried, but I got through it. Once it's all out, remove the cloths from inside the pipe and vacuum a lot. Now is the time to clean stuff up too, as you're about to put the new pipes in. As a best practice, you should clean up the inside of those holes. I used some steel wool; I know some people used scotch bright or even buffing pads. I didn't go overboard with this; I just want to get any grime out of there. Step 15: Install the New Big Pipe At this point you should be elated. You're through the worst. Installing these pipes are a bit difficult, but not bad. If they are not already on there, put the O-Rings on the small pipe. Use the White Lightning grease or whatever you bought and coat the inside of the hole on the engine and the outside of the pipe. Use it liberally. A bit of WD40 wouldn't hurt either. Press it into the hole at the back of the engine and do your best to get it all the way in. This is where a small block of wood and a hammer come in handy; you can use those to tap it in the rest of the way. Do not put the rubber sleeve on it. For the big pipe, install the o-rings and lube everything up good with the grease, both the hole it goes in and the pipe itself. You will also need to grease up the end the rubber part goes on and the other end of the short pipe that the rubber sleeve will slip over. Place the tightening rings over the rubber sleeve as well. Slide the rubber sleeve as far as it will go over the pipe. Push the pipe into the hole, I found a twisting action worked well. I also used my metal screwdriver against the bottom of the engine bay as a lever to slide it in the rest of the way (it required a lot of pressure). You then need to rotate it to line it up with the short end of the pipe. You'll slide the rubber sleeve over it and then tighten up the two rings. NOTE: Be sure to rotate the rings as far down as possible so that the screw does not interfere with the three pipes you're about to place on top of it. The new big pipe should be in place, and you're now done with the hardest part of this job. Step 16: Install the Three Pipes You'll want to put the lid back on the coolant reservoir (replacing the seals Porsche included with the kit), reattach the pipes and tighten up the screws. DO NOT OVERTIGHTEN THE SCREWS. I snapped one clean off. Make sure they're tight, but don't put all your muscle into it. Once on, you are ready to slide those pipes in. You do not need to put the lower bracket at the back on first; I did it after installing the pipes. Again, make sure everything is lubed up well so that any points of friction are well covered. Slide the pipes in. I used by long screwdriver again as a lever to apply the necessary pressure. On both these pipes and the big pipe it looked like I could have gone another 16th of an inch, but nothing leaks so I guess it was far enough. Put the bracket on at the back before you attach the hoses. You'll use your locking pliers again to attach the compression rings. With the bracket in place it is obvious how far up the hoses go. You'll put the upper bracket on, using the spacers for the screws and screwing it down tight. Don't forget to attach the two brackets that hold that electrical cable in place. Not a big deal if you do forget. Step 17: Install Final Pipe Now install that skinny pipe. This one is easy. Don't forget about the small compression ring that goes at the far end. Everything else just clips in. Step 18: Assess Your Work Look over everything and make sure it all looks right. At this point you should have a sealed coolant system. Check all your connections and make sure everything is solid. At this point you're home free, and you should be feeling pretty darn good. Step 19: Fill Up Coolant I use a 50/50 water to coolant ratio… so I mixed everything up with what I had and filled up the coolant tank. Once it was full, I left it overnight and checked in the morning for any fresh coolant. I was totally beat from a long day of working on it and thought putting everything back together fresh in the morning was a good idea. Step 20: Put Everything Back Together You tore it apart, now put it back together. I cleaned everything as I went, so now my engine looks great and I think that's a good idea. You don't need to go overboard, just use some lightly damp, lint free rags and wipe everything down. Porsche should have also provided new seals that go on the bottom of the intake manifold. I replaced mine dutifully, and I am glad I did. The old ones just looked worn out, no way they weren't leaking. Putting everything together is pretty straightforward once you've taken it apart. Just be careful and make sure you get all electrical connections and hoses in back on securely and in the right places (hard to mess that up). Also make sure you remove every bit of masking tape as you go. Final Thoughts I am very, very glad I did this project for two reasons. One, it saved me a ton of money and two, I now know tons more about the engine. Doing this project means I could replace my fuel injectors, spark plugs, injection coils and a host of other things when and if I have to. I know where the throttle body is, and if it's sticking I know where to go to clean it. If I need to replace the starter, I know where it is and how to get to it. I can now take my car on trips without fear of a massive coolant leak. This was the last "major" Cayenne defect for me that needed to be fixed. The water pump & drive shaft were already replaced. With 116,000 miles, I have quite a bit of faith in my car not having a catastrophic failure (knock on wood). At the end of the day, I'm pretty proud of myself for getting this all accomplished, and I hope I've saved some other poor soul a ton of time by writing all of this down. If it does help you out, please reply to this post and let me know.16 points

-

I like pictures when I read a DIY, so I made these up to demonstrate what you are in for when you want to change your plugs. Use these pictures in conjunction with the writeup by ebaker...15 points

-

Lacking any comprehensive instructions about how to remove the a-pillar trim to install hidden wiring for radar detector, GPS and XM antennae, I studied the parts book exploded view (not much help), then just gutted up and attacked the problem. My car is a 997 Targa, but the coupe should be similar and the procedure should be approximately the same on either side of the car. In my car, this technique has allowed me to install a GPS receiver antenna and a satellite radio antenna on a fabricated mounting bracket, along with the radar detector, in a location ahead of the rear view mirror where they are out of my line of sight and without any unsightly antennae marring the exterior of the Porsche bodywork, yet keeping the wiring hidden on the inside. This will also allow the vehicle to be returned easily to its stock configuration if desired. Here’s what worked for me: Note: I first made prying tools to use for popping out the panel fastener clips. These took the form of wedges cut from HDPE plastic stock, about 3/4" thick. Using a screwdriver or the fork type metal prying tools designed to remove door panels could damage the Porsche trim components. 1. First, loosen the coat hook on the b-pillar (at the rear of the door). Do this by moving the shoulder harness adjuster to its lowest position then gently prying inboard at the top of the bezel surrounding the hook; tilt and slide the bezel down and inboard to remove it. Remove the Phillips-head screw holding the hook to the body. This will allow you to pull the coat hook inboard enough without needing to completely remove it. (#1 picture) 2. The trailing edge of the trim piece that runs upward from the base of the a-pillar at the windshield and over the top of the door will now be exposed. Starting from this end and working forward, begin prying the trim piece away from the underlying body. The spring clips holding the trim to the body metal will each let go with a snap. Just get them each to snap loose at this point, without trying to remove the trim piece. The section of the trim piece above the door is flexible enough to bow inward sufficiently that its trailing edge can just be disengaged from behind the coat hook (at least it was on my car, but be careful not to exceed the flex to the point of breakage). If flexing this piece worries you, you will need to remove the shoulder belt anchor point so the hook can be pulled clear, The remaining clips above the door can now be pulled clear of the body. Pull inboard and down, twisting the trim piece slightly as you go forward. Note that the outboard side of the trim piece will also disengage from the rubber door seal molding as you do this. (#2 picture) 3. Working your way forward and down the a-pillar, you can rotate the entire trim piece inward and away from the roof and windshield frame of the body. (#3 picture) Note that there is a plastic tab at the lower edge of the forward end of the trim piece, take care not to rotate the trim piece too far since you could possibly break this tab off. (#4 picture) The tab will insert into a slot in the end of the dashboard (#5 picture) when it is being reassembled. As you rotate the trim piece inward, lower the rear end of the piece while lifting the front end of it clear of the dash pad. This will completely remove the trim piece, which can be set aside. Be certain that you have all of the metal spring clips. Some of these may have bent upon removal and will need to be spread apart so they will firmly remain in their slots in the plastic trim piece when reassembling. (#6 picture) 4. Remove the sun visor, which is held on by two Torx screws, one at each hinge. This is an optional step, but will make it easier to press the wires deeply into the space covered by the trim piece that runs along the top (header) of the windshield. You are now ready to hide the wiring for your radar detector or satellite antenna. 5. Position the device you are wiring and begin pressing the wire into the gap between the windshield gasket and the windshield header trim piece, working your way toward the a-pillar. As the wiring comes past the end of the header trim piece bend it to the rear and down the a-pillar ahead of the slot for the spring clip at the top of the door frame. (#7 picture) Note the wiring in the black convoluted loom seen in the picture is possibly associated with the Targa top and may not be present in a coupe. Wires can be routed inside the hollow black metal structure (the “deformation element”) but should be protected by a plastic split loom or other covering. (#8 picture) 6. Remove the dashboard end cover plate by gently prying its trailing edge out until the clips release. (#9 picture) The rubber door seal must be pulled away from the body in order to remove the end cover plate. This is done by gently pulling the door seal outboard in the area of the end cover plate, the seal merely pulls away from the body pinch seam in this area by pulling it toward the rear. (#10 picture) This will allow the end cover plate to be rotated down and outboard for removal. (#11 picture) Feed the wire(s) downward through the opening between the end of the dash structure and the a-pillar while guiding them by reaching through the hole exposed by the removal of the dashboard end cover plate. Wires can then be routed behind the carpeted kick panel or across the bottom of the glove compartment to where you need them. 7. Reassembly is the reverse of the above procedure. Visually align the spring clips with the body slots they are to clip into and bump them into place with the heel of your hand.14 points

-

One of the problems that I see with many 996/986/997/987 owners complaining about is a lumpy or erratic idle and sometimes sluggish acceleration. I have a quick cure for this problem. In fact, this cure will work for any car that has a throttle body. The issue is that over time a sludgy gunk will build up in the throttle body where the throttle butterfly opens and closes. This gunk will eventually change the airflow characteristics of the gap between the butterfly and the throttlebody which will cause the erratic idle. In addition, this gunk can cause the butterfly the stick as it opens which will effect acceleration. The car's DME will compensate for this buildup over time, but if it gets too thick, then the "Throttle Adaption" will reach its limit, and will throw a code. Many times people think that it is the MAF that is bad, when it is just a dirty throttle body. Notice that the butterfly valve is slightly cracked open. This is for the idle airflow, and that crack can get clogged because of the gunk buildup. The solution is to remove the air cleaner box for access to the throttle body, and simply clean the throttle body with spray carburetor cleaner. Open the butterfly valve with your hand, and wipe out all of the gunk on the backside of the valve, and the inside of the throttle body. You will see a dark brown ring inside the throttle body. This is the buildup you want to remove. Take a rag, wet it with carburetor cleaner, and wipe out the gunk. Be sure to get the edge and the back side of the butterfly valve as well. You will know when you are done because the surfaces that you are cleaning are polished, and easy to see if there is stuff left on them. Here is a picture of what your throttle body should look like after it is cleaned. Notice how shinny the inside is. Don't worry if you spray too much in the engine, when you fire the engine up, all of that stuff will burn off in the combustion chamber. Where does the gunk come from? It is residue from the crankcase vent opening that is right there behind the butterfly. The reason it is there is because there is high vacuum there that will suck the crankcase oil vapors back into the combustion process of the car. Over time oil solids will accumulate there and will form a sticky lip around the opening. This cleaning should be part of your 30,000 mile maintenance as a minimum. However if you have never had your throttle body cleaned, try doing this weekend. You will be amazed at how much better your car runs.13 points

-

A simple inexpensive way to get a better sound a tiny performance gain. In the Fabspeed cold air kit $225.00. For my modification visit home depot and get a 2 inch pvc joint, and 2 inch rubber cap. Remove the air box lid and remove the air muffler 3 screws. Take the pvc joint and from the center measure 1.5 inches and cut off the ends. place the rubber cap in one end and place the pipe through the hole of the air box lid, place the small hose on the intake hose to the pvc expose part with the hose clamp and you are done.13 points

-

I recently installed my mObridge Audio device in my Cayenne Turbo, and wanted to share a bit of experience for anyone considering the same path. I opted to do the install up front in case I needed to access the device for firmware updates. The rest of the options for the device are easily relocated, but to use the SD card access for music or for flashing the firmware requires physical access. The best location I found was the panel directly behind the glove box. There is a single black screw holding the black body panel on, and once removed the entire panel drops down with easy access to the power as well as the rear to the PCM. The wiring was easy EXCEPT the part required to bypass the CDC. There is a loopback device that sends the MOST channel from the CDC to the mObridge box that requires the CDC be dismounted. To remove the CDC is a nightmare, since the body panel in front of it appears to be necessary to remove. I don't have a picture of that, but you can easily imagine how ugly it gets to remove all that. Overall, I'm not real pleased. I expected much better controls and response. You cannot skip songs on a playlist under the current revision of firmware. You can skip around under the "all songs" playlist, but if I want to hear YYZ, I'm screwed on a 160gb iPod. I fully expect it to be resolved in a firmware update, but I'm still a bit pissed off. At least it makes a decent OEM looking install! I'm working on a custom insert for my center dash piece, where the drink holders go. The insert is currently removeable, and created a perfect location to store an ipod (fat chance of actually drinking a soda when riding with me, that's for sure).12 points

-

Start by removing the air filter/metering unit. Two clips hold the Air Fuel Meter cable in place. Disconnect AFM connector and set aside.Remove single bolt holding AF assembly (13mm) and tilt unit back to remove. Set aside. Remove 2 bolts and 1 nut (10mm) holding air pump. One nut holds the Coolant Reservoir. Set aside. I used some string to pull it away from CR. Drain antifreeze by means of drain plug at the bottom of engine. Drain just enough to empty CR, then a little more. I used an aluminum turkey tray to hold antifreeze and reuse. Loosen 3 spring clamps holding hoses to CR. There are two fuel lines that will prevent you from removing the tank from the engine compartment. Loosen (17 & 19mm) them and tuck away (see picture). Disconnect tank sensor. In my car, it seems like it was leaking... (see picture) Slide tank towards engine and maneuver tank out. Be careful with other hoses and electrical connectors. Reverse the procedure to install. Add antifreeze, purge and check for leaks.12 points

-

Note: Part numbers sometimes change without notice. Always double check with your supplier that you have the latest part numbers. Parts you will need: 1 set 996 352 949 03 Front Brake Pads - Porsche (Pagid "S" Pads - Dark Blue - T5104SRS14) 1 set 996 351 088 01 Front Vibration Dampers for Brake Pads (recommended) 2 ea 996 351 959 00 Front Pad Repair Kit (consisting of 2 bolts, springs and securing clips) 2 sets 996 612 365 00 Front and Rear Wear Sensors (if needed) 1 set 996 352 939 03 Rear Brake Pads - Porsche (Pagid "S" Pads - Dark Blue - T5105SRS14) 1 set 964 352 096 01 28 mm Rear Vibration Dampers for Brake Pads (recommended) 1 set 964 352 096 00 30 mm Rear Vibration Dampers for Brake Pads (recommended) 2 ea 996 352 959 00 Rear Pad Repair Kit (consisting of 2 bolts, springs and securing clips) Tools you will need: Jack 19 mm socket for wheel bolts Brake Parts Cleaner (do not use other cleaners) Needle Nose Pliers Punch (for driving the pins out) Hammer or soft mallet Caliper Spreader or large Water Pump Pliers Note: The brake pads must be replaced (both sets of pads per axle) if the brake pad warning indicator lights up, but no later than when there is a residual pad thickness of 2 mm. If brake pad wear is indicated by the warning light, the warning contact sensor (sender including wire and plug connection) must also be replaced. Replacing the warning contact sensor can be avoided by replacing the brake pads no later than when the pad thickness is 2.5 mm. Warning contact sensors with a worn wire core must be replaced. However, if only the plastic part of the warning contact is worn, replacement is not necessary. Also, do not disassemble the caliper when changing the vibration dampers (or painting the calipers) as Porsche does not sell inner seal kits. Jack up the vehicle at the lift points provided and remove the a wheel (you will need to do this for each wheel). Visually inspect the brake pads for wear. The wear limit is reached when the pad has a residual thickness of 2 mm (or less). Front Pad Replacement Remove the retainer (arrow) and extract the retainer pin inwards. Pull out the warning contact wire on the brake caliper and remove the warning contacts from the brake pad plates. Remove brake pads with a brake pad puller or use the water pump Pliers to spread the pads. (Photos are courtesy of Greg Heumann) Important Notes: Pull out brake pads together with the vibration dampers. If this is not possible (depending on wear of the brake pads), use a spatula to detach the vibration dampers from the brake pad plate before removing the pads. In both cases, first set back the brake pads as far as possible with the piston resetting fixture. If necessary, first remove some brake fluid by suction from the brake fluid reservoir. If necessary, carefully push back the piston to its original position. Fit new vibration dampers in the pistons. Do this by removing protective film from the vibration dampers before installation. Insert the brake pads. Caution: The pad backing plates (rear side of the brake pads) must not be greased. Note: If you are using Pagid (or some other 3rd party pads) you will likely have to drill the pad for the wear sensors. Just look at the old pads and drill the sensor holes in the same location. Fit new expanding spring, new retaining pin and new retainer (retaining bracket). These parts are available as a repair set and must be 'renewed' each time the pads are changed. Insert the warning contact wire and warning contacts. Firmly press the brake pedal several times with the vehicle stationary so that the brake pads assume their fit in accordance with the operating state. Next, check and, if necessary, correct the brake fluid level. Bedding in the brake pads New brake pads require a bedding-in period of approximately 125 miles. Not until then do they achieve their best friction and wear coefficient. During this period, the brakes should be subjected to full stress only in emergencies when traveling at high speed. ------------------------------------------------------------------------------------------------------------------------------ Rear Pad Replacement Remove the retainer (arrow) and extract the retainer pin inwards. Pull out the warning contact wire on the brake caliper and remove the warning contacts from the brake pad plates. Remove brake pads with a brake pad puller or use the Water pump Pliers to spread the pads. Important Notes: Pull out brake pads together with the vibration dampers. If this is not possible (depending on wear of the brake pads), use a spatula to detach the vibration dampers from the brake pad plate before removing the pads. In both cases, first set back the brake pads as far as possible with the piston resetting fixture. If necessary, first remove some brake fluid by suction from the brake fluid reservoir. If necessary, carefully push back the piston to its original position. Fit new vibration dampers in the pistons. There are 2 sizes of vibration dampers. The lower piston is 28 mm (smaller) and upper piston is 30 mm (larger). Be sure you get them in the right places. As you install them you will need to remove the protective film from the vibration dampers. Insert the brake pads. Note: The pad backing plates (rear side of the brake pads) must not be greased. Fit new expanding spring, new retaining pin and new retainer (retaining bracket). These parts are available as a repair set and must be 'renewed' each time the pads are changed. Insert the warning contact wire and warning contacts. Firmly press the brake pedal several times with the vehicle stationary so that the brake pads assume their fit in accordance with the operating state. Finally, check and, if necessary, correct the brake fluid level. Bedding in the brake pads New brake pads require a bedding-in period of approximately 125 miles. Not until then do they achieve their best friction and wear coefficient. During this period, the brakes should be subjected to full stress only in emergencies when traveling at high speed.12 points

-

There have a been a few occurances of the cabrio top not fully completing the cycle, or simply refusing to open or close. If the hand brake light is on, very likely it is a low hydraulic fluid condition. The work below shows step by step how to add the fluid to the system. Tools needed: 5 mm allen wrench Flat screwdriver Children medicine syringe with small hose 1 Bottle of hydraulic fluid. Porsche is the recommended, I have used John Deere below with no problems after 4 weeks of filling: The steps for the process: 1. Open the top partially to the position shown 2. Pull the cables that the keep the rearmost part of the top secured to the car. One cable per side, the separate the cable from the connection in the car. 3. Let top move towards the close postion and move it out of the way. 4. Use a flat screw driver to remove the 4 plugs that keep the rear carpet in place. Remove the carpet, starting at the top as shown 5. Not a bad time to vacuum this piece while it is out. If you have kids, remove the lollipop sticks :P The work area will look like this: 6. This is the system pump you are looking for. Notice the screw where the Allen wrench will go to. Remove the screw, and keep a magnet pick up tool nearby if it fall down. 7. Use a flashlight on the oppsite side and shine direcly to the reservior. You will be able to clearly see the level and the gap to full. The fullmark is in the front below the screw removed. 8. To fill the top, use the syringe filled with fluid and insert the hose into the hole below. WARNING, the brass washer may fall off if you are not carefull, you can remove it or leave it and chance it. It probably won't move 9. Replace the screw, using fingers first to get it started. Take your time, will not be easy the first round. Finalize withe Allen wrench 10. Replace the carpet (did you clean it?) and the secure it with the plugs. Move the top back in place and secure the cables to the car. Open and close the top a few times. Enjoy the open air And remember, nothing races like a Porsche, but nothing runs like a deer12 points

-