It seems that there are more and more cases of these faults appearing, and as some of our cars are reaching 10-12 years old, it is hardly surprising. I've compiled this information from past personal experience on both of my 996s, reading about others on here and other forums, referring to the workshop manual and wiring diagrams, and applying some logic. Hopefully you might find it useful, and save some grief when troubleshooting.

DOOR MICROSWITCHES

There are seven microswitches in each door which control the alarm system.

Two are separate switches:

a] One on the outside door handle. This switch is used to sense that the handle is lifted.

b] One on the inside door handle, which has the same function.

When the car is unlocked and either handle is lifted, this signals the alarm control module (ACM) to lower the appropriate window by 10mm, and turn on the interior lights. As soon as the door opens, another switch inside the door lock (explained later) tells the ACM that the door is open, which holds the window down until the door is closed, when the window is raised, and the dimming timer on the interior lights is started. Once the car is locked, the outside handle switches are ignored by the ACM.

The remaining five switches are inside the door lock assembly:

c] One switch senses if the door is open or closed.

d] One senses that the key has been turned to the 'lock' position.

e] Another senses that the key has been turned to the 'unlock' position.

f] One senses that the door lock motor has reached the 'lock' position.

g] Another senses that the door lock motor has reached the 'unlock' position.

TYPICAL FAULTS

All these microswitches can be problematic, and it is common for one or more to fail at some time. These are some of the common failures and symptoms:

1) The door window won't drop when lifting a handle. This is usually the handle microswitch which has failed.

2) The window drops, but goes back up when the door opens, or when the handle is released. This can be the handle microswitch, or more likely the 'door open/closed microswitch' ( c ) has stuck. Because the system thinks the door is still closed, it sends the window back up.

3) Door window won't go up the last 10mm. This is likely to be the 'door open/closed microswitch' ( c ) stuck in the opposite sense to (2). The system thinks the door is still open, so won't allow the window to go back up. Note that in this case the door will still lock, but you may get a single-beep from the alarm horn.

4) Door will not lock with key. The 'key lock' microswitch (d) is broken. This is very rare, as this microswitch is hardly ever used – most times the car is locked by remote.

5) Door will not unlock with key. The 'key lock' microswitch (e) is broken. This is also very rare, for the same reason.

6) Door locks, and then immediately unlocks, usually accompanied by a double-beep from the alarm horn. This is the 'door locked' microswitch (f). The locking motor physically operates the door lock, but the microswitch to sense this has failed/stuck. The ACM promptly unlocks the car. In this case, the only way to lock the door is to use the emergency locking procedure. Turn the key in the door to the lock position and back three times in quick succession.

7) The door unlocks, but there is a beep or double-beep from the alarm horn. This is the 'door unlocked' microswitch (g). Although the door is unlocked, the ACM has not recognised that. The alarm will not sound, as turning the key in the lock has deactivated it.

FIXES

The inside and outside handle microswitches are available separately, and are not too expensive. Although alternative equivalent switches may be available, the genuine Porsche switch comes with a connector and wiring, so it makes sense to use an original. Part Numbers:

Inside handle microswitch: 996.613.123.00 (Same both sides)

Outside handle microswitch: 996.613.125.00 (Left) / 996.613.126.00 (Right)

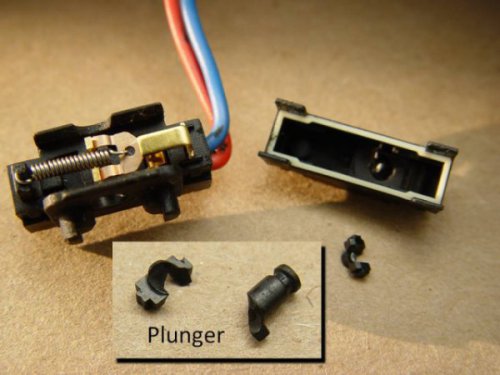

The door lock microswitches are not available separately. You have to buy the complete door lock assembly, at a cost of around $120. It has been known for people to repair the offending switch though. This is a picture of a typical failure of a 'door open/close' microswitch (courtesy of another RennTech member):

You can see that the plastic plunger has broken, jamming the switch lever inside. These switches are (apparently) made by Burgess, but as yet the source and part number are unknown. There are several other similar standard switches on the market for around $2, and people have stripped down the new switch and rebuilt the old one with the plunger from the new one.

OTHER SWITCHES IN THE ALARM SYSTEM

The other switches and contacts in the alarm system are to monitor the lid closures:

Front lid microswitch

Rear lid microswitch

Oddment compartment microswitch

Glove box microswitch

Radio contact (to detect radio theft)

An open compartment or switch failure will cause a single-beep of the alarm horn on locking. A system error will cause a double-beep.

Other elements of the system include an interior monitoring sensor (in the overhead lighting), an alarm readiness light (on the dashboard in the centre) and a central locking button (on the dashboard). Options are a tilt sensor (next to the battery or under the left-hand seat) and an alarm siren (next to the battery).